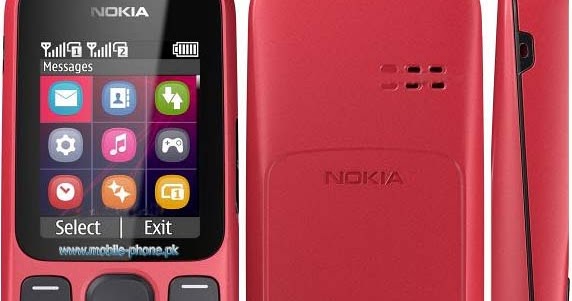

D0%B4%D1%80%D0%B0%D0%B9%D0%B2%D0%B5%D1%80%20%D0%B4%D0%BB%D1%8F%20%D0%BD%D0%BE%D0%BA%D0%B8%D0%B0%203120%20classic' alt='Nokia Rh 19 Flash File' title='Nokia Rh 19 Flash File' />BEST BB5 Easy Service Tool by Infinity Team is a new flash and repair tool for Nokia mobile phones. It might be useful when your customer asks to save. HackersRussia лучший в Рунете сайт по радиосвязи, проводной связи и безопасности. Fun mobile gadgets at Discount Prices flashing keypads, datacables, unlocking cables, infrared cables, phone covers, sim cards, dual sim covers, chargers. Coduri secrete Nokia Articole. Anonim. Telefoane nokia care se pot decoda prin coduri 1. N Gage, N Gage. QD, N Gage. QDa.

Polycarbonate Wikipedia. Polycarbonates PC are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code RIC and are identified as Other, 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A BPA. StructureeditPolycarbonates received their name because they are polymers containing carbonate groups OCOO. A balance of useful features, including temperature resistance, impact resistance and optical properties, positions polycarbonates between commodity plastics and engineering plastics. ProductioneditThe main polycarbonate material is produced by the reaction of bisphenol A BPA and phosgene. COCl. 2. The overall reaction can be written as follows The first step of the synthesis involves treatment of bisphenol A with sodium hydroxide, which deprotonates the hydroxyl groups of the bisphenol A. HOC6. H42. CMe. 2 2 Na. OH Na. 2OC6. H42. CMe. 2 2 H2. OThe diphenoxide Na. OC6. H42. CMe. 2 reacts with phosgene to give a chloroformate, which subsequently is attacked by another phenoxide. The net reaction from the diphenoxide is Na. Nokia Rh 19 Flash File' title='Nokia Rh 19 Flash File' />OC6. H42. CMe. 2 COCl. OCOC6. H42. CMe. Na. Cl. In this way, approximately one billion kilograms of polycarbonate is produced annually. Many other diols have been tested in place of bisphenol A, e. The cyclohexane is used as a comonomer to suppress crystallisation tendency of the BPA derived product. Tetrabromobisphenol A is used to enhance fire resistance. Tetramethylcyclobutanediol has been developed as a replacement for BPA. An alternative route to polycarbonates entails transesterification from BPA and diphenyl carbonate HOC6. H42. CMe. 2 C6. H5. O2. CO 1n OCOC6. H42. CMe. 2n 2 C6. H5. OHThe diphenyl carbonate was derived in part from carbon monoxide, this route being greener than the phosgene method. The ring opening polymerization of cyclic carbonates has been investigated. Properties and processingeditPolycarbonate is a durable material. Although it has high impact resistance, it has low scratch resistance. Therefore, a hard coating is applied to polycarbonate eyewearlenses and polycarbonate exterior automotive components. The characteristics of polycarbonate compare to those of polymethyl methacrylate PMMA, acrylic, but polycarbonate is stronger and will hold up longer to extreme temperature. Polycarbonate is highly transparent to visible light, with better light transmission than many kinds of glass. Polycarbonate has a glass transition temperature of about 1. C 2. 97 F,7 so it softens gradually above this point and flows above about 1. C 3. 11 F. 8 Tools must be held at high temperatures, generally above 8. C 1. 76 F to make strain free and stress free products. Low molecular mass grades are easier to mold than higher grades, but their strength is lower as a result. The toughest grades have the highest molecular mass, but are much more difficult to process. Day Shred Torrent Iso Game'>30 Day Shred Torrent Iso Game. Unlike most thermoplastics, polycarbonate can undergo large plastic deformations without cracking or breaking. Enemy At The Gates Pc Game Download. As a result, it can be processed and formed at room temperature using sheet metal techniques, such as bending on a brake. Even for sharp angle bends with a tight radius, heating may not be necessary. This makes it valuable in prototyping applications where transparent or electrically non conductive parts are needed, which cannot be made from sheet metal. PMMAAcrylic, which is similar in appearance to polycarbonate, is brittle and cannot be bent at room temperature. Main transformation techniques for polycarbonate resins extrusion into tubes, rods and other profiles including multiwallextrusion with cylinders calenders into sheets 0. Due to its chemical properties it is not conducive to laser cutting. Polycarbonate may become brittle when exposed to ionizing radiation above 2. Gy Jkg. 9. A bottle made from polycarbonate. ApplicationseditElectronic componentseditPolycarbonate is mainly used for electronic applications that capitalize on its collective safety features. Being a good electrical insulator and having heat resistant and flame retardant properties, it is used in various products associated with electrical and telecommunications hardware. It can also serve as a dielectric in high stability capacitors. However, commercial manufacture of polycarbonate capacitors mostly stopped after sole manufacturer Bayer AG stopped making capacitor grade polycarbonate film at the end of year 2. Construction materialsedit. Polycarbonate sheeting in a greenhouse. The second largest consumer of polycarbonates is the construction industry, e. Data storageeditA major application of polycarbonate is the production of Compact Discs, DVDs, and Blu ray Discs. These discs are produced by injection molding polycarbonate into a mold cavity that has on one side a metal stamper containing a negative image of the disc data, while the other mold side is a mirrored surface. Automotive, aircraft, railway, and security componentseditIn the automotive industry, injection molded polycarbonate can produce very smooth surfaces that make it well suited for sputter deposition or evaporation deposition of aluminium without the need for a base coat. Decorative bezels and optical reflectors are commonly made of polycarbonate. Due to its low weight and high impact resistance, polycarbonate is the dominant material for making automotive headlamp lenses. However, automotive headlamps require outer surface coatings because of its low scratch resistance and susceptibility to ultraviolet degradation yellowing. The use of polycarbonate in automotive applications is limited to low stress applications. Stress from fasteners, plastic welding and molding render polycarbonate susceptible to stress corrosion cracking when it comes in contact with certain accelerants such as salt water and plastisol. It can be laminated to make bullet proof glass, although bullet resistant is more accurate for the thinner windows, such as are used in bullet resistant windows in automobiles. The thicker barriers of transparent plastic used in tellers windows and barriers in banks are also polycarbonate. So called theft proof large plastic packaging for smaller items, which cannot be opened by hand, is uniformly made from polycarbonate. Lockheed Martin F 2. The cockpit canopy of the Lockheed Martin F 2. Raptor jet fighter is made from a piece of high optical quality polycarbonate, and is the largest piece of its type formed in the world. Dj Mixer Free Download Full Version For Laptop more. Kereta Api Indonesia, the major railway operator in Indonesia, uses polycarbonate solid sheet for their engine and passenger cars fleet since 2. Niche applicationseditPolycarbonate, being a versatile material with attractive processing and physical properties, has attracted myriad smaller applications. The use of injection molded drinking bottles, glasses and food containers is common, but the use of BPA in the manufacture of polycarbonate has stirred serious controversy see Potential hazards in food contact applications, leading to development and use of BPA free plastics in various formulations. Laboratory safety goggles.

Polycarbonate Wikipedia. Polycarbonates PC are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code RIC and are identified as Other, 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A BPA. StructureeditPolycarbonates received their name because they are polymers containing carbonate groups OCOO. A balance of useful features, including temperature resistance, impact resistance and optical properties, positions polycarbonates between commodity plastics and engineering plastics. ProductioneditThe main polycarbonate material is produced by the reaction of bisphenol A BPA and phosgene. COCl. 2. The overall reaction can be written as follows The first step of the synthesis involves treatment of bisphenol A with sodium hydroxide, which deprotonates the hydroxyl groups of the bisphenol A. HOC6. H42. CMe. 2 2 Na. OH Na. 2OC6. H42. CMe. 2 2 H2. OThe diphenoxide Na. OC6. H42. CMe. 2 reacts with phosgene to give a chloroformate, which subsequently is attacked by another phenoxide. The net reaction from the diphenoxide is Na. Nokia Rh 19 Flash File' title='Nokia Rh 19 Flash File' />OC6. H42. CMe. 2 COCl. OCOC6. H42. CMe. Na. Cl. In this way, approximately one billion kilograms of polycarbonate is produced annually. Many other diols have been tested in place of bisphenol A, e. The cyclohexane is used as a comonomer to suppress crystallisation tendency of the BPA derived product. Tetrabromobisphenol A is used to enhance fire resistance. Tetramethylcyclobutanediol has been developed as a replacement for BPA. An alternative route to polycarbonates entails transesterification from BPA and diphenyl carbonate HOC6. H42. CMe. 2 C6. H5. O2. CO 1n OCOC6. H42. CMe. 2n 2 C6. H5. OHThe diphenyl carbonate was derived in part from carbon monoxide, this route being greener than the phosgene method. The ring opening polymerization of cyclic carbonates has been investigated. Properties and processingeditPolycarbonate is a durable material. Although it has high impact resistance, it has low scratch resistance. Therefore, a hard coating is applied to polycarbonate eyewearlenses and polycarbonate exterior automotive components. The characteristics of polycarbonate compare to those of polymethyl methacrylate PMMA, acrylic, but polycarbonate is stronger and will hold up longer to extreme temperature. Polycarbonate is highly transparent to visible light, with better light transmission than many kinds of glass. Polycarbonate has a glass transition temperature of about 1. C 2. 97 F,7 so it softens gradually above this point and flows above about 1. C 3. 11 F. 8 Tools must be held at high temperatures, generally above 8. C 1. 76 F to make strain free and stress free products. Low molecular mass grades are easier to mold than higher grades, but their strength is lower as a result. The toughest grades have the highest molecular mass, but are much more difficult to process. Day Shred Torrent Iso Game'>30 Day Shred Torrent Iso Game. Unlike most thermoplastics, polycarbonate can undergo large plastic deformations without cracking or breaking. Enemy At The Gates Pc Game Download. As a result, it can be processed and formed at room temperature using sheet metal techniques, such as bending on a brake. Even for sharp angle bends with a tight radius, heating may not be necessary. This makes it valuable in prototyping applications where transparent or electrically non conductive parts are needed, which cannot be made from sheet metal. PMMAAcrylic, which is similar in appearance to polycarbonate, is brittle and cannot be bent at room temperature. Main transformation techniques for polycarbonate resins extrusion into tubes, rods and other profiles including multiwallextrusion with cylinders calenders into sheets 0. Due to its chemical properties it is not conducive to laser cutting. Polycarbonate may become brittle when exposed to ionizing radiation above 2. Gy Jkg. 9. A bottle made from polycarbonate. ApplicationseditElectronic componentseditPolycarbonate is mainly used for electronic applications that capitalize on its collective safety features. Being a good electrical insulator and having heat resistant and flame retardant properties, it is used in various products associated with electrical and telecommunications hardware. It can also serve as a dielectric in high stability capacitors. However, commercial manufacture of polycarbonate capacitors mostly stopped after sole manufacturer Bayer AG stopped making capacitor grade polycarbonate film at the end of year 2. Construction materialsedit. Polycarbonate sheeting in a greenhouse. The second largest consumer of polycarbonates is the construction industry, e. Data storageeditA major application of polycarbonate is the production of Compact Discs, DVDs, and Blu ray Discs. These discs are produced by injection molding polycarbonate into a mold cavity that has on one side a metal stamper containing a negative image of the disc data, while the other mold side is a mirrored surface. Automotive, aircraft, railway, and security componentseditIn the automotive industry, injection molded polycarbonate can produce very smooth surfaces that make it well suited for sputter deposition or evaporation deposition of aluminium without the need for a base coat. Decorative bezels and optical reflectors are commonly made of polycarbonate. Due to its low weight and high impact resistance, polycarbonate is the dominant material for making automotive headlamp lenses. However, automotive headlamps require outer surface coatings because of its low scratch resistance and susceptibility to ultraviolet degradation yellowing. The use of polycarbonate in automotive applications is limited to low stress applications. Stress from fasteners, plastic welding and molding render polycarbonate susceptible to stress corrosion cracking when it comes in contact with certain accelerants such as salt water and plastisol. It can be laminated to make bullet proof glass, although bullet resistant is more accurate for the thinner windows, such as are used in bullet resistant windows in automobiles. The thicker barriers of transparent plastic used in tellers windows and barriers in banks are also polycarbonate. So called theft proof large plastic packaging for smaller items, which cannot be opened by hand, is uniformly made from polycarbonate. Lockheed Martin F 2. The cockpit canopy of the Lockheed Martin F 2. Raptor jet fighter is made from a piece of high optical quality polycarbonate, and is the largest piece of its type formed in the world. Dj Mixer Free Download Full Version For Laptop more. Kereta Api Indonesia, the major railway operator in Indonesia, uses polycarbonate solid sheet for their engine and passenger cars fleet since 2. Niche applicationseditPolycarbonate, being a versatile material with attractive processing and physical properties, has attracted myriad smaller applications. The use of injection molded drinking bottles, glasses and food containers is common, but the use of BPA in the manufacture of polycarbonate has stirred serious controversy see Potential hazards in food contact applications, leading to development and use of BPA free plastics in various formulations. Laboratory safety goggles.